Technology Development

Raw Material Procurement

Arnos controls the quality of valves from the source. Raw materials must be inspected every time and stored in accordance with international standards. Arnos Valve can supply cast iron, ductile iron, carbon steel, forged steel, stainless steel, molybdenum steel, duplex stainless steel, etc.

Casting Line

We have our own casting line. Chemical and physical analysis will be carried out before casting to meet international standards to better ensure the quality of the valve. Our casting lines can not only control the quality, but also reduce the production cost.

Machining

Arnos has a variety of processing workshops such as CNC lathes, general lathes, and large-scale processing workshops. The machining and dimensional accuracy of the valves are all completed by our well-trained craftsmen with high precision.

Spraying and Warehouse

In order to ensure the beauty of the valve, we have an environmentally friendly automatic painting workshop and professional painting engineers. The warehouse covers an area of 2000 square meters and can deliver conventional valves on time.

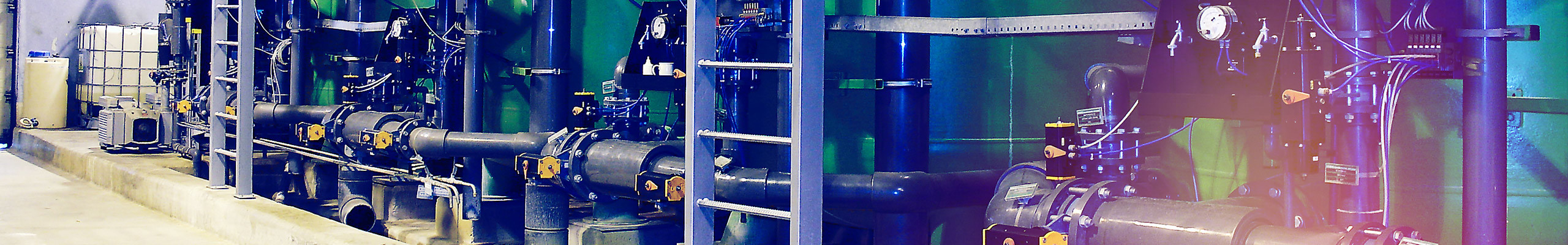

Assembling & Inspections

All valves manufactured by Arnos are assembled and inspected in our factory.

Every valve is inspected and pressure tested after assembly. We use different media for different valves, such as steam, water, compressed air, etc. Only qualified products will be sent to the spraying workshop.