Products

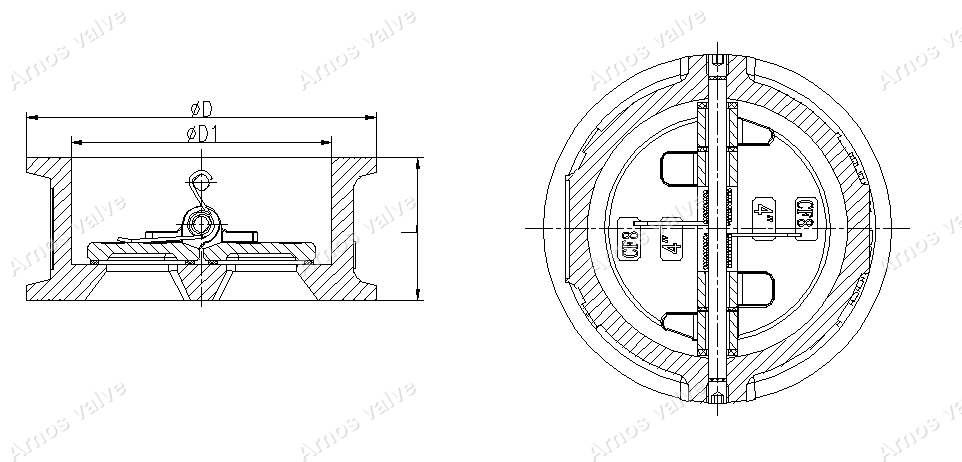

Butterfly Check Valve

Classification:

Summary

PRODUCT DETAILS

Product Model: DH77X-10Q、DH77X-16Q、DH77X-150LB

Nominal Pressure: PN10/PN16/Class 150

Suitable Temperature: -20~120℃

Applicable Medium:Clear water, neutral liquid, Oils, etc.

Body Materials: Ductile Iron

Application field: Municipal construction, water treatment, water supply and drainage, water conservancy projects, etc.

Product Introduction

Wafer check valve is mainly used at the water supply and drainage pipe network wells or the water pump outlet of fire fighting, petrochemical, light textile, papermaking and high-rise buildings. It is a safety device to prevent the backflow pressure difference of pipeline medium and forming water hammer impact and water pump reversal when the water pump is stopped.

1.Design Standards

| Design and manufacturing standards: | JB/T 8937 Design and Manufacture Standard: JB/T 8937 |

| Structure length standard: | GB/T 12221 Structure Length Standard: GB/T 12221 |

| Test standards: | GB/T 13927 Test Standard:GB/T 13927 |

2.Main Parts Materials

| Valve body material: | DI Body Materials: DI |

| Valve plate material: | DI、CF8、CF8M、CF3、CF3M Disc Materials: DI、CF8、CF8M、CF3、CF3M |

| Valve seat material: | EPDM、NBR Seat Materials: EPDM、NBR |

| Valve spindle material: | SS420、SS304 Stem Materials: SS420、SS304 |

3.Product Advantages

Small size, light weight, compact structure and convenient maintenance;

The valve plate is of dual type, which can close quickly under the elastic moment of the spring.

Due to the fast closing effect, it can prevent the medium from backflowing , and eliminate the strong effect of water hammer;

The valve body structure has small length, good rigidity, safety and reliability;

Surface coating: Epoxy powder coating is adopted, with strong adhesion and good weather resistance. It can be used indoors and outdoors.

The numerically-controlled machine tool grinds the sealing surface of the body, with good flatness and surface roughness, which can ensure the zero pressure sealing of wafer check valve.

The rubber and valve body are joined by vulcanization process, and the adhesive strength is higher than 1.7mpa, and it can avoid the falling off of the valve seat during use

4.Parameters

| DN | φD | φD1 | L | DN | φD | φD1 | L | |

| 2″ | DN50 | 101 | 65 | 43 | 12″ | 378 | 310 | 114 |

| 2.5″ | DN65 | 118 | 80 | 46 | 14″ | 438 | 360 | 127 |

| 3″ | DN80 | 132 | 94 | 64 | 16″ | 489 | 410 | 140 |

| 4″ | DN100 | 157 | 117 | 64 | 18″ | 539 | 450 | 152 |

| 5″ | DN125 | 186 | 145 | 70 | 20″ | 594 | 505 | 152 |

| 6″ | DN150 | 213 | 170 | 76 | 24″ | 695 | 624 | 178 |

| 8″ | DN200 | 272 | 224 | 89 | 28″ | 810 | 720 | 229 |

| 10″ | DN250 | 328 | 265 | 114 | 32″ | 917 | 825 | 241 |

Keywords:

Butterfly type check valve

Leave a message